INTRODUCTION:

Flawless bonding, drying and transport. The Double Facer from BHS Corrugated does it all – from micro-flute to heavy triple-corrugated board. How productive your corrugator is largely depends on the performance of your Double Facer, especially in markets with a high proportion of double flutes. This factor is generally what determines the pace at which a corrugator runs. That is why, in developing the Double Facer, BHS Corrugated opted to prioritize speed, laying the groundwork for achieving maximum speeds with double flutes and even heavier triple-corrugated board.

Some Functions Of These Machine Are As Follows:

Platerol loading system:

The perfect combination of strengths

The Platerol loading system combines the advantages of rolls and pressure shoes for highly efficient heat transfer and optimal web connections. The customized features ensure consistently good bonding by providing the ideal combination of line pressure and surface pressure. This makes it possible to avoid caliber losses even with narrow working widths. As a result, there are fewer rejects, even with fast quality changes. The system is fully automated and equipped with a number of specific speed and safety features. It can be operated from the control console as well as directly from the control station.

Technical Features:

For excellent user-friendliness

The Machine Control Center (MCC) forms the interface between the operator and the machine. The MCC monitors the system. Its integrated features, including an operating hours counter and maintenance system, enables it to also perform complex error diagnostics. All information about the current state of the machine is compiled and processed here and represented structurally. So, information is clearly presented and instantly available to the operator. The MCC also allows you to test, modify and save settings. The special belt boasts even more enhanced features like higher wear resistance and excellent drying performance. In addition, it ensures the optimal flatness of your corrugated board. The MCC also comes with a permanently integrated cleaning program.

Pressure Shoes And Hotplates:

Features for precise heating

The high, consistent surface pressure of the pressure shoes facilitates excellent heat transfer between the hotplates and corrugated board. This significantly enhances the effectiveness of the heat sections. An even load across the working width prevents the corrugated board from being pressed together. The hotplate is mounted on a stable base. This makes it possible to ensure that the hotplates are in a flat position in all operating states. Heat is transmitted exclusively through this plate, allowing for the fastest possible reactions to production changes. The result – much less production waste! Thanks to the large front doors and height-adjustable loading system, the hotplates practically clean themselves.

Dual Boost Technology:

Innovative high technology for your Double Facer

The performance of your Double Facer is a critical factor for the productivity of your entire corrugator: this applies in particular to achieving the best possible maximum and average production speeds. For physical reasons, production speeds are often severely limited in this area of the corrugator. Whether you are running double or triple wallgrades: investment in proven technical developments on the Double Facer will always sustainably increase the performance of the entire corrugator.

With “DualBoost", BHS Corrugated has developed a specific module for the critical infeed of the Double Facer, to achieve a quick return by significantly increasing the production speed. The many years of market leadership and the pronounced innovation potential that BHS Corrugated can bring to bear with the aim of maximum economic efficiency for the operators of corrugated box plants is impressively reflected in this exclusive additional module.

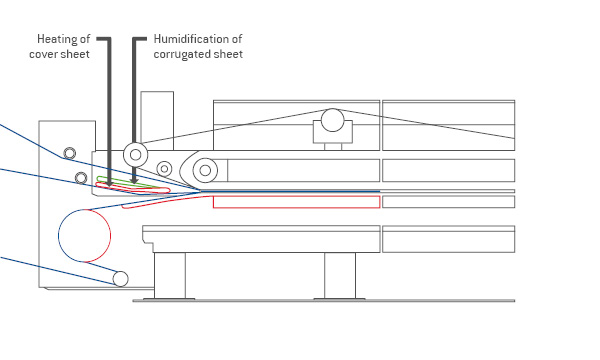

The name DualBoost already gives a clear indication of how the module works. "Dual" refers to the clever combination of heating the lower top web liner in a functional unit with steam moistening of the upper, single-wall web. The high efficiency of the unit results in a "boost" of the gluing process as far as double-wall or heavier grammages are concerned. The optimum positioning of the DualBoost in the specially optimized infeed stand maximizes the effectiveness of the process, as the webs finally run together. The so-called "double kiss effect" is also significantly reduced by the special web guide, which leads to just before the gluing point. This leads to a constantly even gluing across the working width without edge gluing problems, again, the optimal design of the infeed stand is decisive for this.

The two independent functions - liner heating / corrugated web moistening - can be individually controlled depending on speed and board grade. The outflowing steam, which is directed in the running direction of the corrugated board, conditions the paper and starch at the flute tips prior to bonding with the liner. At the same time, the inner volume of the corrugated board is filled with saturated steam as an energy carrier, thus increasing the energy inside the corrugated board. This leads to faster heating and conditioning, which further reduces the risk of the corrugated board drying out. The spraying unit sprays saturated steam where it is really needed. This helps to save energy permanently and reduces energy losses.

The intelligent control system ensures that the amount of steam flowing out is not only in relation to the line speed, but also in accordance with the current paper width being run. The openings of the spray unit are arranged in such a way that they are maintenance-free. This ensures minimal maintenance and cleaning of the entire system. The increased energy level of the steam/air volume introduced into the web shortly before the gluing point results in a much more effective heat transfer. In this way, the use of DualBoost technology enables the adhesive strength of the webs to be increased by up to ten percent.

DualBoost units installed have resulted in production increases averaging up to 30 m/min with double wall qualities and up to 20 m/min with triple wall.

Machine Safety:

The Double Facer from BHS Corrugated meets the requirements of EN 1010-1 and EN 1010-5, the industry standard of the European CE Machinery Directive.